The RF MEMS acronym stands for radio frequency microelectromechanical system, and refers to components of which moving sub-millimeter-sized parts provide RF functionality. RF functionality can be implemented using a variety of RF technologies. Besides RF MEMS technology, ferrite, ferroelectric, GaAs, GaN, InP, RF CMOS, SiC, and SiGe technology are available to the RF designer. Each of the RF technologies offers a distinct trade-off between cost, frequency, gain, large scale integration, lifetime, linearity, noise figure, packaging, power consumption, power handling, reliability, repeatability, ruggedness, size, supply voltage, switching time and weight

There are various types of RF MEMS components, such as RF MEMS resonators and self-sustained oscillators with low phase noise , RF MEMS tunable inductors, and RF MEMS switches, switched capacitors and varactors.

Switches, switched capacitors and varactors

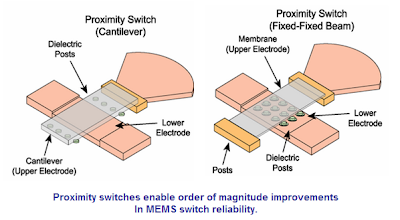

RF MEMS switches, switched capacitors and varactors, which can replace field effect transistor (FET) switches and PIN diodes, are classified by actuation method (electrostatic, electrothermal, magnetic, piezoelectric), by axis of deflection (laterally, vertically), by circuit configuration (series, shunt), by clamp configuration (cantilever, fixed-fixed beam), or by contact interface (capacitive, ohmic) . Electrostatically-actuated RF MEMS components offer low insertion loss and high isolation, high linearity, high power handling and high Q factor, do not consume power, but require a high supply voltage and hermetic wafer level packaging (WLP) (anodic or glas frit wafer bonding) or single chip packaging (SCP) (thin film capping, liquid crystal polymer (LCP) or low temperature co-fired ceramic (LTCC) packaging).

RF MEMS switches were pioneered by Hughes Research Laboratories, Malibu, CA , Raytheon, Dallas, TX , and Rockwell Science, Thousand Oaks, CA , during the nineties. The component shown in Fig. 1, is a center-pulled capacitive fixed-fixed beam RF MEMS switch, developed and patented by Raytheon in 1994. A capacitive fixed-fixed beam RF MEMS switch is in essence a micro-machined capacitor with a moving top electrode - i.e. the beam

From an electromechanical perspective, the components behave like a mass-spring system, actuated by an electrostatic force. The spring constant is a function of the dimensions of the beam, of the Young's modulus, of the residual stress and of the Poisson ratio of its material. The electrostatic force is a function of the capacitance and the bias voltage. Knowledge of spring constant and mass allows for calculation of the pull-in voltage, which is the bias voltage necessary to pull-in the beam, and of the switching time.

From an RF perspective, the components behave like a series RLC circuit with negligible resistance and inductance. The up- and down-state capacitance are in the order of 50 fF and 1.2 pF, which are functional values for millimeter-wave circuit design. Switches typically have a capacitance ratio of 30 or higher, while switched capacitors and varactors have a capacitance ratio of about 1.2 to 10. The loaded Q factor is between 20 and 50 in the X-, Ku- and Ka-band.

RF MEMS switched capacitors are capacitive fixed-fixed beam switches with a low capacitance ratio. RF MEMS varactors are capacitive fixed-fixed beam switches which are biased below pull-in voltage. Other examples of RF MEMS switches are ohmic cantilever switches, and capacitive single pole N throw (SPNT) switches based on the axial gap wobble motor .

Microfabrication

An RF MEMS fabrication process allows for integration of SiCr or TaN thin film resistors (TFR), metal-air-metal (MAM) capacitors, metal-insulator-metal (MIM) capacitors, and RF MEMS components. An RF MEMS fabrication process can be realized on a variety of wafers: fused silica (quartz), borosilicate glass, LCP, sapphire, and passivated silicon and III-V compound semiconducting wafers. As shown in Fig. 2, RF MEMS components can be fabricated in class 100 clean rooms using 6 to 8 optical lithography steps with a 5 μm contact alignment error, whereas state-of-the-art monolithic microwave integrated circuit (MMIC) and radio frequency integrated circuit (RFIC) fabrication processes require 13 to 25 lithography steps. The essential microfabrication steps are

•Deposition of the bias lines (Fig. 2, step 3)

•Deposition of the electrode layer (Fig. 2, step 4)

•Deposition of the dielectric layer (Fig. 2, step 5)

•Deposition of the sacrificial spacer (Fig. 2, step 6)

•Deposition of seed layer and subsequent electroplating (Fig. 2, step 7)

•Beam definition, release and critical point drying (Fig. 2, step 8)

RF MEMS fabrication processes, unlike barium strontium titanate (BST) or lead zirconate titanate (PZT) ferroelectric and MMIC fabrication processes, do not require electron beam lithography, molecular beam epitaxy (MBE), or metal organic chemical vapor deposition (MOCVD). With the exception of the removal of the sacrificial spacer, the fabrication steps are compatible with a CMOS fabrication process.

Applications

Applications of RF MEMS resonators and switches include oscillators and routing networks. RF MEMS components are also applied in radar sensors (passive electronically scanned (sub)arrays and T/R modules) and software-defined radio (reconfigurable antennas, tunable band-pass filters).

Antennas

Polarization and radiation pattern reconfigurability, and frequency tunability, are usually achieved by incorporation of lumped components based on III-V semiconductor technology, such as single pole single throw (SPST) switches or varactor diodes. However, these components can be readily replaced by RF MEMS switches and varactors in order to take advantage of the low insertion loss and high Q factor offered by RF MEMS technology. In addition, RF MEMS components can be integrated monolithically on low-loss dielectric substrates, such as borosilicate glass, fused silica or LCP, whereas III-V semiconducting substrates are generally lossy and have a high dielectric constant. A low loss tangent and low dielectric constant are of importance for the efficiency and the bandwidth of the antenna.

The prior art includes an RF MEMS frequency tunable fractal antenna for the 0.1–6 GHz frequency range , and the actual integration of RF-MEMS on a self-similar Sierpinski gasket antenna to increase its number of resonant frequencies, extending its range to 5GHz, 14GHz and 30GHz , , an RF MEMS radiation pattern reconfigurable spiral antenna for 6 and 10 GHz , an RF MEMS radiation pattern reconfigurable spiral antenna for the 6–7 GHz frequency band based on packaged Radant MEMS SPST-RMSW100 switches , an RF MEMS multiband Sierpinski fractal antenna, again with integrated RF MEMS switches, functioning at different bands from 2.4 to 18 GHz , and a 2-bit Ka-band RF MEMS frequency tunable slot antenna .

Filters

RF bandpass filters are used to increase out-of-band rejection, if the antenna fails to provide sufficient selectivity. Out-of-band rejection eases the dynamic range requirement of low noise amplifier LNA and mixer in the light of interference. Off-chip RF bandpass filters based on lumped bulk acoustic wave (BAW), ceramic, surface acoustic wave (SAW), quartz crystal, and thin film bulk acoustic resonator (FBAR) resonators have superseded distributed RF bandpass filters based on transmission line resonators, printed on substrates with low loss tangent, or based on waveguide cavities. RF MEMS resonators offer the potential of on-chip integration of high-Q resonators and low-loss bandpass filters. The Q factor of RF MEMS resonators is in the order of 1000-1000 .

Tunable RF bandpass filters offer a significant size reduction over switched RF bandpass filter banks. They can be implemented using III-V semiconducting varactors, BST or PZT ferroelectric and RF MEMS switches, switched capacitors and varactors, and yttrium iron garnet (YIG) ferrites. RF MEMS technology offers the tunable filter designer a compelling trade-off between insertion loss, linearity, power consumption, power handling, size, and switching time .

Phase shifters

RF MEMS phase shifters have enabled wide-angle passive electronically scanned arrays, such as lenses, reflect arrays, subarrays and switched beamforming networks, with high effective isotropically radiated power (EIRP), also referred to as the power-aperture product, and high Gr/T. EIRP is the product of the transmit gain, Gt, and the transmit power, Pt. Gr/T is the quotient of the receive gain and the antenna noise temperature. A high EIRP and Gr/T are a prerequisite for long-range detection. The EIRP and Gr/T are a function of the number of antenna elements per subarray and of the maximum scanning angle. The number of antenna elements per subarray should be chosen to optimize the EIRP or the EIRP x Gr/T product.

Nombre: Lenny D. Ramirez C.

Asignatura: CRF

Direccion: http://reference.findtarget.com/search/RF%20MEMS/

Ver blogg: http://lennyramirez-crf.blogspot.com/